ITALY – The Consorzio del Parmigiano Reggiano (CFPR) has tied up with Kaasmerk Matec (Kaasmerk), a leading producer of casein cheesemarks and p-Chip Corporation (p-Chip), a digital tracing technology inventor, to launch a line of food-safe and secure traceability digital labels for its Parmigiano Reggiano cheese wheels.

The new technology will deliver previously unseen levels of traceability, inventory tracking and control, product authentication, quality-assurance testing, product serialization, and consumer safety.

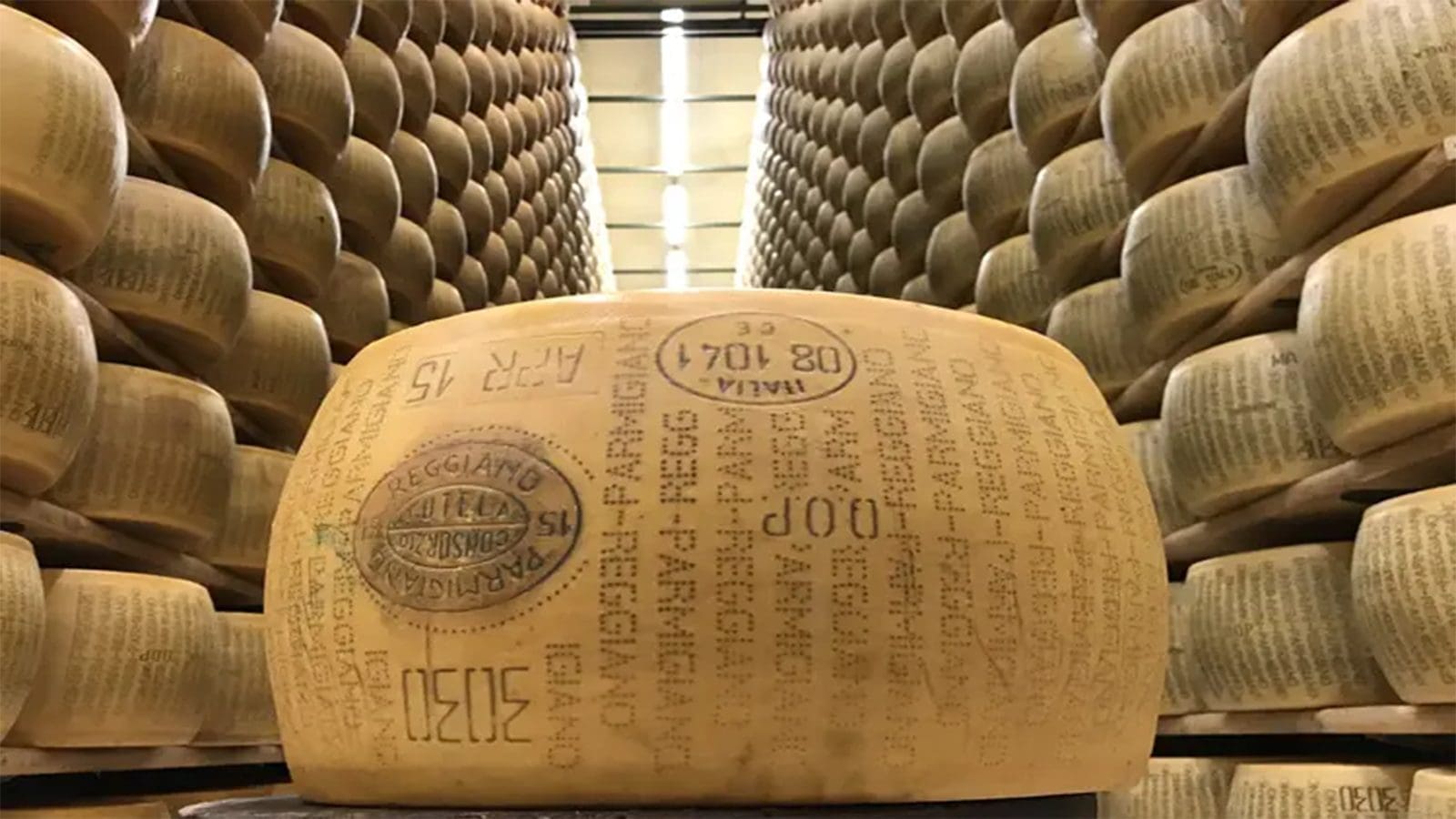

Founded in 1934, the Consorzio del Parmigiano Reggiano is a consortium for all producers of Parmigiano Reggiano cheese.

Parmigiano Reggiano is one of the world’s oldest and most famous cheeses, and it is a product that symbolizes Italian produce.

Since its establishment, the consortium has worked to convey the value of its product globally and distinguish it from similar-sounding products on the market that do not meet its strict requirements for production and area of origin.

“By being the first to incorporate these secure digital labels onto our cheese wheels, we can continue to ensure consumer safety, bringing the traceability and the authentication of our products to meet industry 4.0 technological targets,” said Nicola Bertinelli, President of the Consorzio del Parmigiano Reggiano.

Previously, a casein label with a unique and sequential alphanumeric code has been applied to each Parmigiano Reggiano cheese wheel way from 2002.

However, things are set to change with the launch of p-Chip’s new line of secure, digital tracking labels for the industry. CFPR is breaking new ground by embedding these p-Chip micro transponders into 2D codes, QR codes, and/or data-matrix codes.

The result is an innovative, food-safe digital tag that takes CFPR’s food safety and security a step beyond the government requirement, according to Cision PR Newswire.

Kaasmerk Matec and p-Chip Corporation partnered to complete this innovation program for a p-Chip device integrated into casein label, an industry-standard, protein-based type of food/cheese identification method.

Next-generation visibility

The innovation combines food-safe Casein labels with the p-Chip micro transponder—a blockchain crypto-anchor that creates a digital “twin” for physical items. This scannable new food tag is smaller than a grain of salt and highly durable, delivering next-generation visibility and traceability to the Consorzio del Parmigiano Reggiano.

“We’re pleased to partner with a leading global brand as Consorzio del Parmigiano Reggiano is, to bring world-class, disruptive tracing technology to the food industry.

“By integrating p-Chip micro transponders into Casein tags, CFPR can better control its inventory, protect and differentiate its products against look and sound-alike brands and have access to unmatchable track-and-trace technology to protect itself in the case of recalls or other issues. I look forward to working with Consorzio del Parmigiano Reggiano as they realize the full potential this technology holds for their business,” said Joe Wagner, CEO of p-Chip Corporation.

CFPR has for the past two years conducted extensive testing of the p-Chip/Kaasmerk Matec Casein label and approved the label’s technical use for the authentication and digital traceability of Parmigiano Reggiano cheese.

“For more than 100 years, we’ve worked with artisan cheese producers to deliver casein cheesemarks that provide an invaluable level of protection for their recipes, helping to safeguard the passion and craftsmanship they bring to production of their cheeses,” said Winus Sloot, Managing Director of Kaasmerk Matec.

“We are pleased to collaborate with p-Chip to develop this smart digital label that will track and trace CFPR the Consorzio del Parmigiano Reggiano ‘s bulk cheeses from start to finish, providing additional protection and to both CFPR and consumers, as the label is highly resistant to tampering,” he added.

The new smart digital food labels will be added to 100,000 CFPR bulk cheese wheels in the second quarter of 2022 as the final phase of large-scale “testing”, before evaluating the possibility of extending this technology to the entire production of Parmigiano Reggiano.

Liked this article? Subscribe to Food Safety Africa News, our regular email newsletters with the latest news insights from Africa and the World’s food safety, quality and compliance. SUBSCRIBE HERE