U.S – InfinityQS International Inc., the leading provider of statistical process control software and services, has announced that it has been named a Top Software & Technology Provider by Food Logistics magazine for the 11th year in a row.

Food Logistics is the only publication exclusively dedicated to covering the movement of product and information through the cold food and beverage supply chain.

Formerly known as the FL100+, the annual award list honors software and technology providers who ensure a safe, efficient, and reliable global cold food and beverage supply chain.

InfinityQS was recognized for its digital quality management solutions, Enact and ProFicient, that help cold food and beverage manufacturers improve product quality, comply with food safety standards, reduce costs and waste, and make data-driven business decisions.

Michael Lyle, President and CEO of InfinityQS said quality and safety are vital at every step of the cold food and beverage supply chain. He however noted that the prevalent use of outdated, paper-based quality control methods makes it challenging for manufacturers to ensure consistent adherence to safety and quality standards.

“At InfinityQS, we’re committed to helping food and beverage manufacturers retire the pencil and paper. By embracing modern solutions for real-time, data-driven quality assurance, manufacturers can reach new levels of quality, compliance, and business performance,” he said.

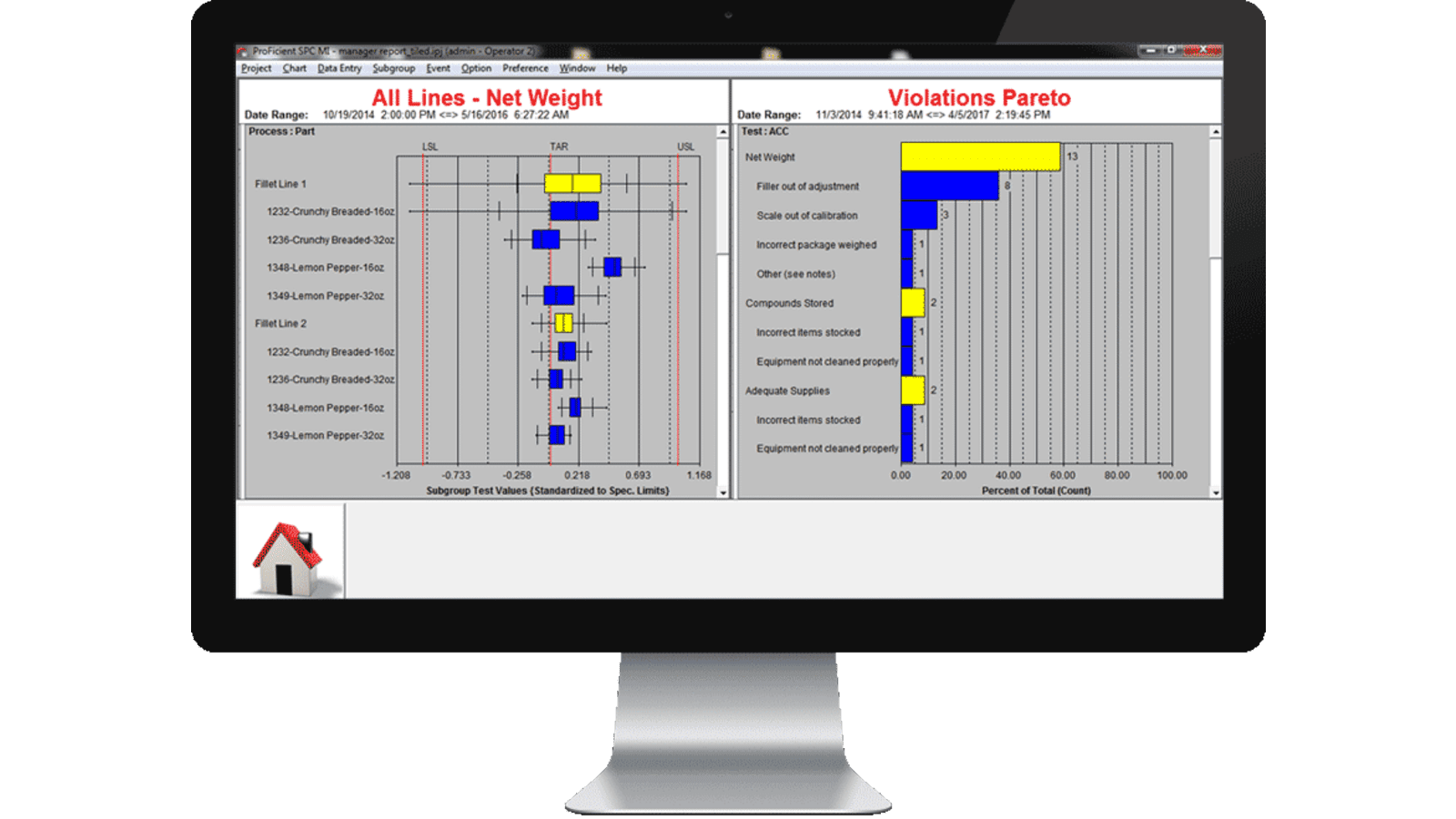

Powered by Statistical Process Control (SPC), InfinityQS software centralize, standardize, and aggregate data from across all production lines and plants in an enterprise, delivering the visibility needed to monitor food quality and safety for the entire production cycle—from incoming ingredients to finished goods.

Cloud-based solutions

The company’s cloud-based solutions provide cold food and beverage manufacturers with insight into supplier performance to ensure only the highest quality raw materials are incorporated into final products.

During the manufacturing process, the software automates data collection and analysis to detect quality issues or concerning trends as they happen—speeding response times and preventing defects before they occur.

Food manufacturers can take their quality data a step further, using advanced analysis tools and data visualizations to easily compare cross-plant data, quickly identify opportunities for continuous quality improvement, and ultimately gain a competitive advantage.

Notably, InfinityQS has made it easier than ever to digitally transform quality management for more efficient, safe, and resilient cold food and beverage production. The company’s cloud-based solutions offer rapid deployment and scalability, enabling food manufacturers to solve immediate challenges and see rapid returns on their investment.

Furthermore, InfinityQS recently introduced a new Proof-of-Concept approach to ease the transition to the cloud.

These small-scale deployments focus on one manufacturing process to help new clients get accustomed to the software, get buy-in from stakeholders, and lay a strong foundation for successful enterprise-wide deployment.

“Software developments and emerging technologies are what make the world go ‘round. They’re what make supply chains move, even when the world stops. They’re what keeps people, products, and plants safe. They provide traceability, visibility, efficiency, and credibility. And, the winners from this year’s award prove that there are no limitations to what software and technology can do in the supply chain space,” says Marina Mayer, Editor-in-Chief of Food Logistics and Supply & Demand Chain Executive.

Liked this article? Subscribe to Food Safety Africa News, our regular email newsletters with the latest news insights from Africa and the World’s food safety, quality and compliance. SUBSCRIBE HERE