EUROPE – This year’s Gulfood Manufacturing expo in Dubai will see the introduction of a brand-new range of multihead weighers from Ishida Europe, a global leader in weighing and inspection solutions.

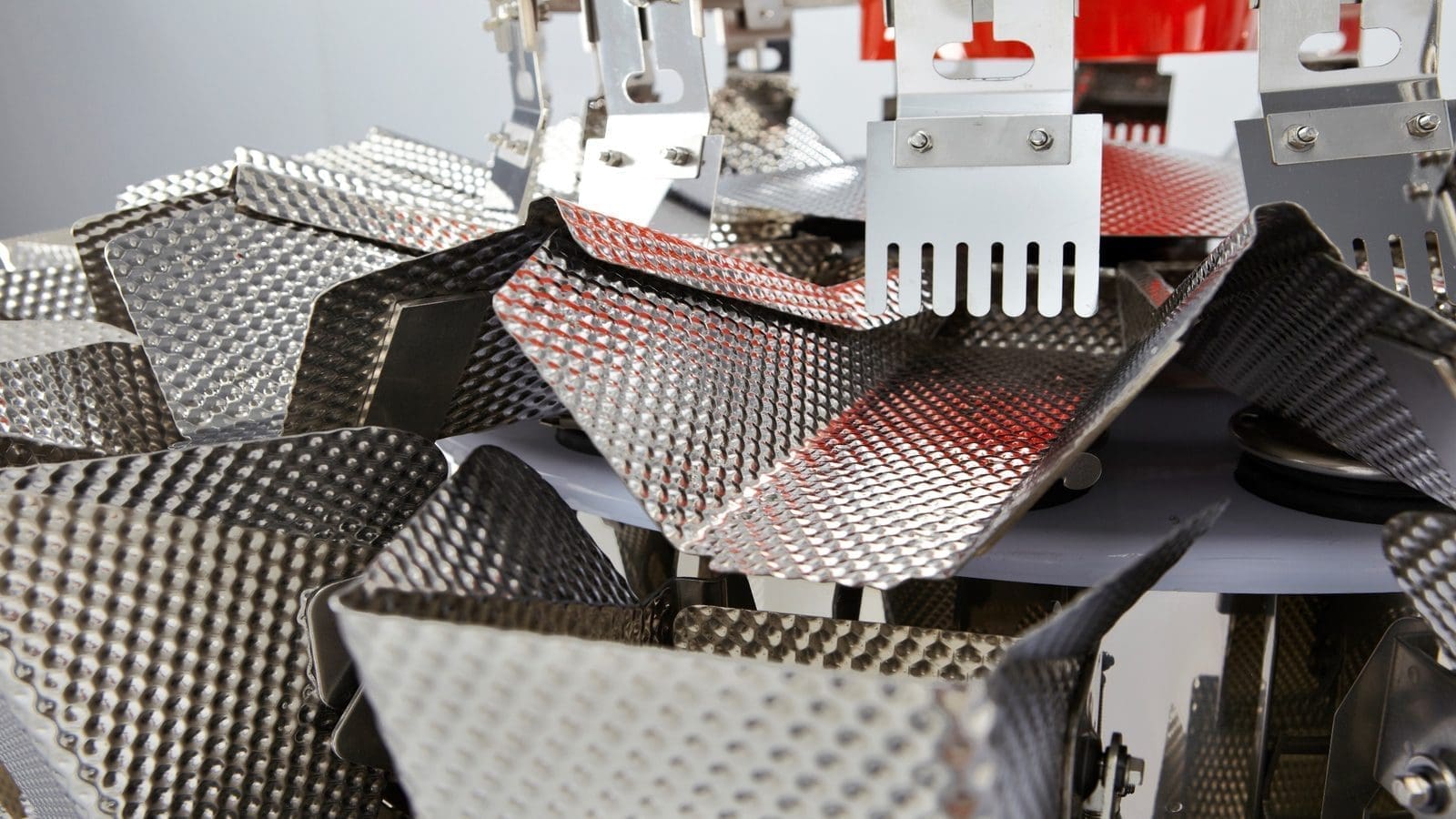

According to Ishida, the new line of multihead weighers, which represents the company’s 11th generation, will provide unmatched levels of speed and precision, particularly when handling more difficult items.

The Inspira iTPS combines the company’s top-of-the-range RV multihead weigher with its high-performance Inspira rotary bagmaker.

The method operates at speeds of up to 200 bags per minute (bpm) for extruded snacks and up to 150 bpm for potato chips, delivering nearly no giveaway and higher than 99% efficiency.

The bagmaker can handle a range of films, including standard, metallized, recyclable, and biodegradable, as well as gusseted and block bottom bags, with the use of advanced software and servo-controlled variable seal time, jaw temperature, and jaw pressure.

The Inspira is outfitted with Ishida’s tried-and-true iTPSTM software, which makes it easy to fully integrate it with other weighing and inspection systems from the company.

It offers a high-speed solution for leak detection, fill level monitoring, and pack weight management and is demonstrated with an integrated Ishida TSC sealtester and force balance checkweigher.

AAF (Auto Air-Fill) feedback software is also specified with the TSC sealtester, which automatically monitors and modifies the pack inflation level on the bagmaker.

The CHW-214 multihead weigher from Ishida provides a low-cost alternative that is perfect for expanding capacity and utilizing automation for the first time in developing food businesses.

It offers great value and a quick return on investment, usually paying for itself in just one year.

The weigher can process dry, free-flowing goods at up to 90 packs per minute, including pasta, cereal, crackers, cookies, and snack foods.

The two cutting-edge Ishida X-ray inspection systems give food producers strong solutions for quality control and food safety.

Unpacked chicken fillets can have up to 400 low-density wish, rib, and fan bones accurately detected by the IX-G2-F Dual Energy.

To minimize false detections and reduce product waste, the scanner can also detect uneven and overlapping items.

The Ishida IX-GN-4044-S offers best-in-class foreign body identification and quality control, assuring unparalleled food safety and brand protection for a variety of packaged and unpacked products.

At high inspection speeds, the machine can detect a wide range of foreign objects, including aluminum, tin, glass, stone, hard rubber, dense plastic, Teflon, PVC, bones, and shells. In addition, thanks to Ishida’s Genetic Algorithm (GA) technology, users can enhance the X-ray system’s sensitivity to particular objects.

The machine also has quality control features for counting components, estimating weight, and identifying missing or broken parts, product defects, and deformities.

Both X-ray systems include Ishida’s comprehensive service package, which guarantees a Total Cost of Ownership over a five-year period of less than 3% annually.

For all the latest food safety news from Africa and the World, subscribe to our NEWSLETTER, follow us on Twitter and LinkedIn, like us on Facebook and subscribe to our YouTube channel.