UK/U.S – Oli-Tec has developed a smart label technology it claims will help industry and consumers manage waste better, a process which began in 2015.

Oli-Tec Technology has been developed by a team of experienced, and highly creative people who joined forces to develop a technology to solve the problem of monitoring the shelf-life of products.

Almost one-third of all food produced for human consumption is wasted or lost each year.

In developed countries, consumers throw away 286 million tons of cereal products per year. According to the Food and Agriculture Organization (FAO), in Europe alone, 29 million tons of dairy products are lost or wasted each year.

A total of 1.3 million tons of food is lost and wasted each year, which is estimated to be enough to feed two billion people, or ten times the entire US population.

This happens when food is stored at the wrong temperature, or to a larger extent, due to consumers not using food labels effectively or not knowing when food is still good to eat.

Oli-Tec is committed to changing consumer behavior through its new innovation. By “filling a gap” in the time and temperature indicator labeling market, the startup hopes consumers will make “smarter choices” when it comes to product lifespan.

“We designed Oli-Tec label technology with converters, retailers and consumers in mind. We wanted to make technology that could be easily integrated into complex processes in the supply chain and in the store, so that each label could play a role in reducing waste.

“We also aimed to develop a simple visual indicator to help consumers see when food is going off. They can then decide whether to use it, freeze it or cook it,” explained Nick Richardson, CEO of Oli-Tech. explained.

A 2021 study published in the Journal of Nutrition and Behavioral Education suggested that only 64% of US adults could correctly explain the meaning of the “best to use” label. Only 44.8% were able to describe the meaning of “use by”.

Mirroring the product’s cycle of decay

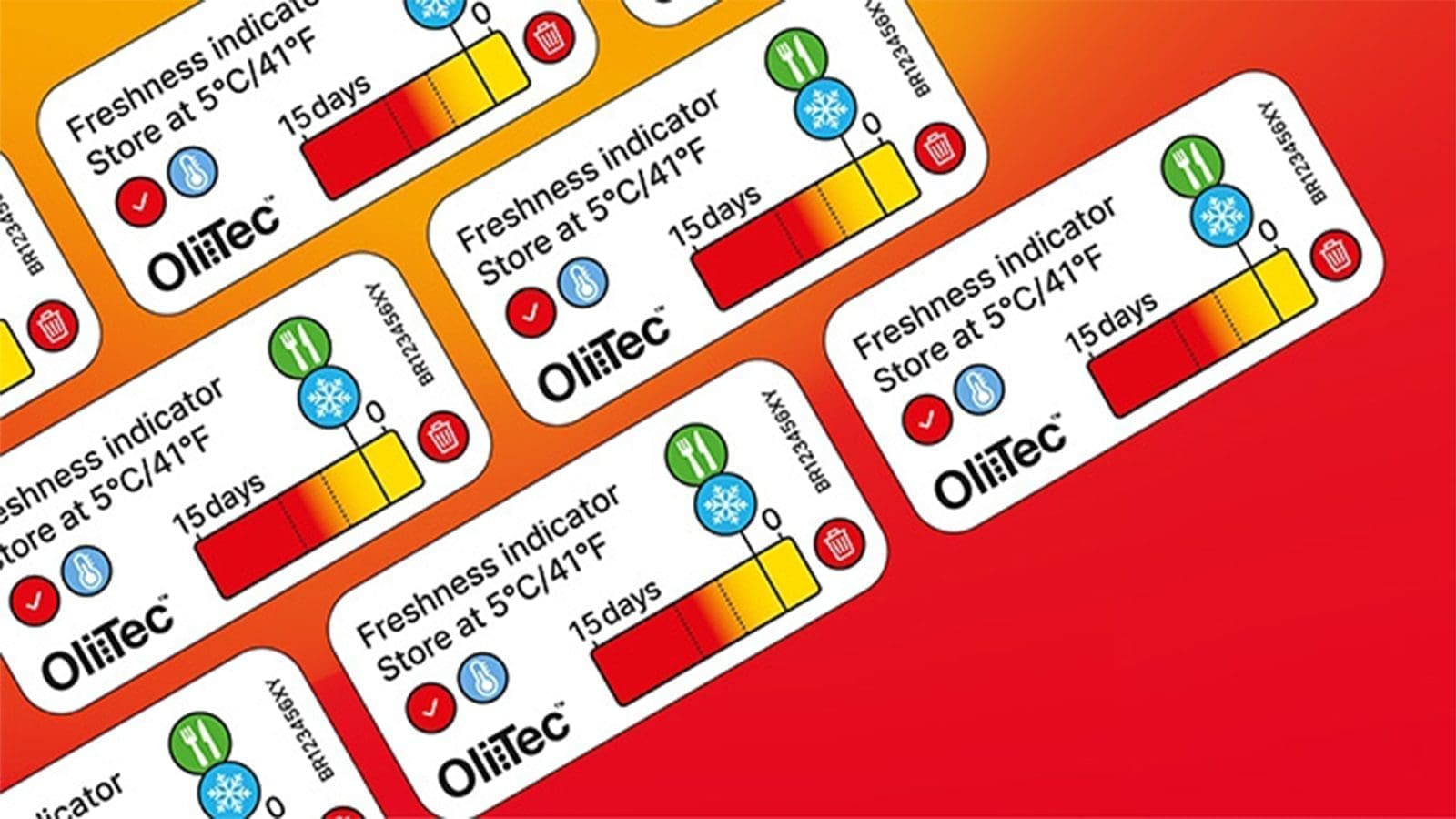

Oli-Tec’s smart label technology is temperature and time sensitive. The label is basically designed to “mirror the cycle of decay” of the labeled product. The 100% recyclable polypropylene label can be affixed to any product with a shelf life of five to 15 days, reports Food Navigator.

Its time window changes from yellow to red when product quality deteriorates over time. Being time sensitive, the diffusion line accelerates when the product is at high temperatures and slows down at low temperatures.

The thermometer icon is displayed in blue, but only when the product is stored at the correct temperature.

For consumers, the benefits are clear: the label provides a lifecycle monitor for fresh, prepackaged or frozen foods so they know when perishables are “at their best.”

However, Oli-Tec is certain that the labeling technology will benefit others in the food supply chain. Distributors will able to detect supply chain problems at an early stage while the retailers will be able to manage their stores more efficiently and better control products with a shorter shelf life. This will in turn result in lower discounts.

For consumers, the benefits are clear: the label provides a lifecycle monitor for fresh, prepackaged or frozen foods so they know when perishables are “at their best.”

Having completed the initial validation of the labeling technology, Oli-Tec is now looking to test its effectiveness in retail, manufacturing, pharmaceutical, supply chain and logistics.

However, early indications are that smart labels can make a big difference: a study in Denmark found that using smart labels reduced food waste in stores by 20%.

Oli-Tec believes that similar reductions could be achieved in consumers’ homes if they had smart labels with a visual “call to action” indicator instead of relying on labels with “use by” or “best before” dates.

Liked this article? Subscribe to Food Safety Africa News, our regular email newsletters with the latest news insights from Africa and the World’s food safety, quality and compliance. SUBSCRIBE HERE