U.S – PerkinElmer, a global provider of innovative solutions, has launched its MicrofastTM ready-to-use microbial count plates for food safety testing on a global scale.

The quick, convenient and accurate MicrofastTM microfilm plates can spot contaminants across multiple sample types.

Markedly, the microbial count plates are part of the PerkinElmer’s wide-ranging food safety and quality solutions, including instruments, software, testing kits, reagents, and more.

With the latest launch, the company aims to solidify its global foothold in the food safety testing space.

The new microfilm plates are developed to offer efficient, effective, and user-friendly quantification of aerobic, E. coli, coliform, Enterobacteriaceae, yeast and mold, and staphylococcus aureus contamination in dairy, meat/poultry, fruit, vegetable, baked goods and environmental surface samples.

All six plate types have received the AOAC Performance Tested Methods certification.

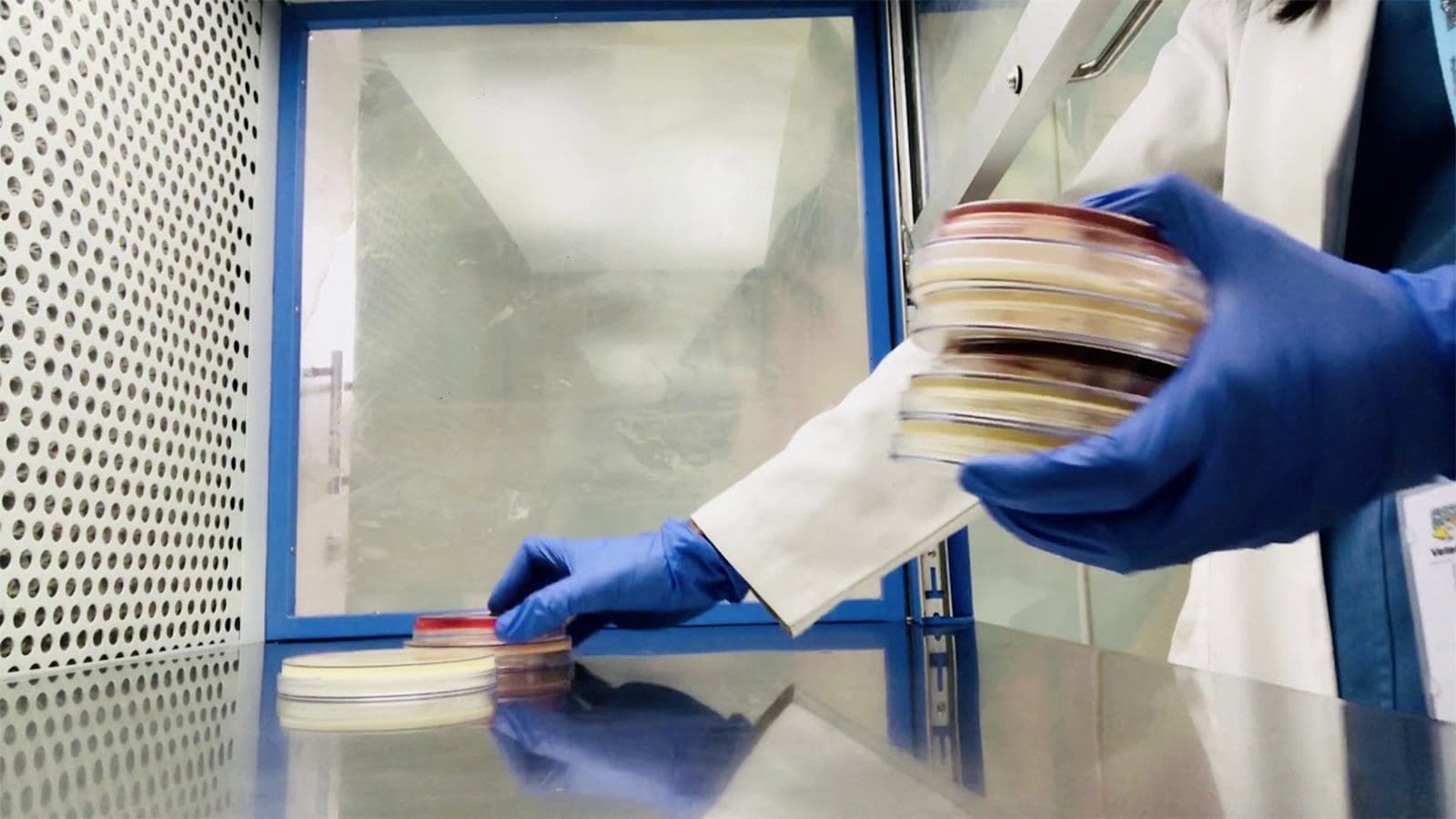

Intended for food companies and contract labs, the highly sensitive and accurate kits feature a simple, three-step workflow that has 66% lesser steps than traditional approaches.

Users can put the liquid sample on the leak-free culture area, featuring automatic diffusion, and lower the film without pressing, incubate the plate and wait for the new-generation microbial coloration to reflect the rapid proliferation of microbial contaminants.

According to the company, the AOAC-approved microbial count plates have lesser complexity and labor demands yet provide a quality result, throughput and ease of use.

Using microfilm plates, data becomes available sooner, presenting results within 48 and 72 hours for yeasts and mold compared with 120 hours and five days, respectively, through the use of traditional culture methods. This helps in timely decision-making and maximizes sample throughput.

Additionally, the microbial plates minimize human error with the help of standardized protocols and offer a small footprint to save space in incubators and storage areas.

In line with PerkinElmer’s commitment to sustainability, the microfilm/cardboard design of the plates lowers plastic waste in the lab.

In March 2022, PerkinElmer launched its FT-IR liquid food testing platform, including instruments, software and streamlined workflows.

This includes the LQA300 TM FT-IR system for wine, and the LactoScope 300TM FT-IR system for liquid dairy, which leverage PerkinElmer’s FT-IR Spectroscopy technology and expand the company’s FT-IR dairy portfolio, respectively.

In line with a report by Grand View Research, the global food safety testing market was estimated to be US$18 billion in 2018, witnessing a CAGR of 7.7% between 2019 and 2025.

Factors like growing demand for packaged and processed food, rising incidents of chemical contamination in food processing industries, and growing consumer awareness about food safety are expected to drive the market.

Liked this article? Subscribe to Food Safety Africa News, our regular email newsletters with the latest news insights from Africa and the World’s food safety, quality and compliance. SUBSCRIBE HERE