U.S – ProSpection Solutions, a U.S.-based manufacturer of inspection technology systems for the food industry, has developed an optimized low-density foreign material inspection system by employing Ethernet for Control Automation Technology (EtherCAT)- a real-time Industrial Ethernet technology- and PC-based control technology from Beckhoff Automation, the technology leader in PC-based automation.

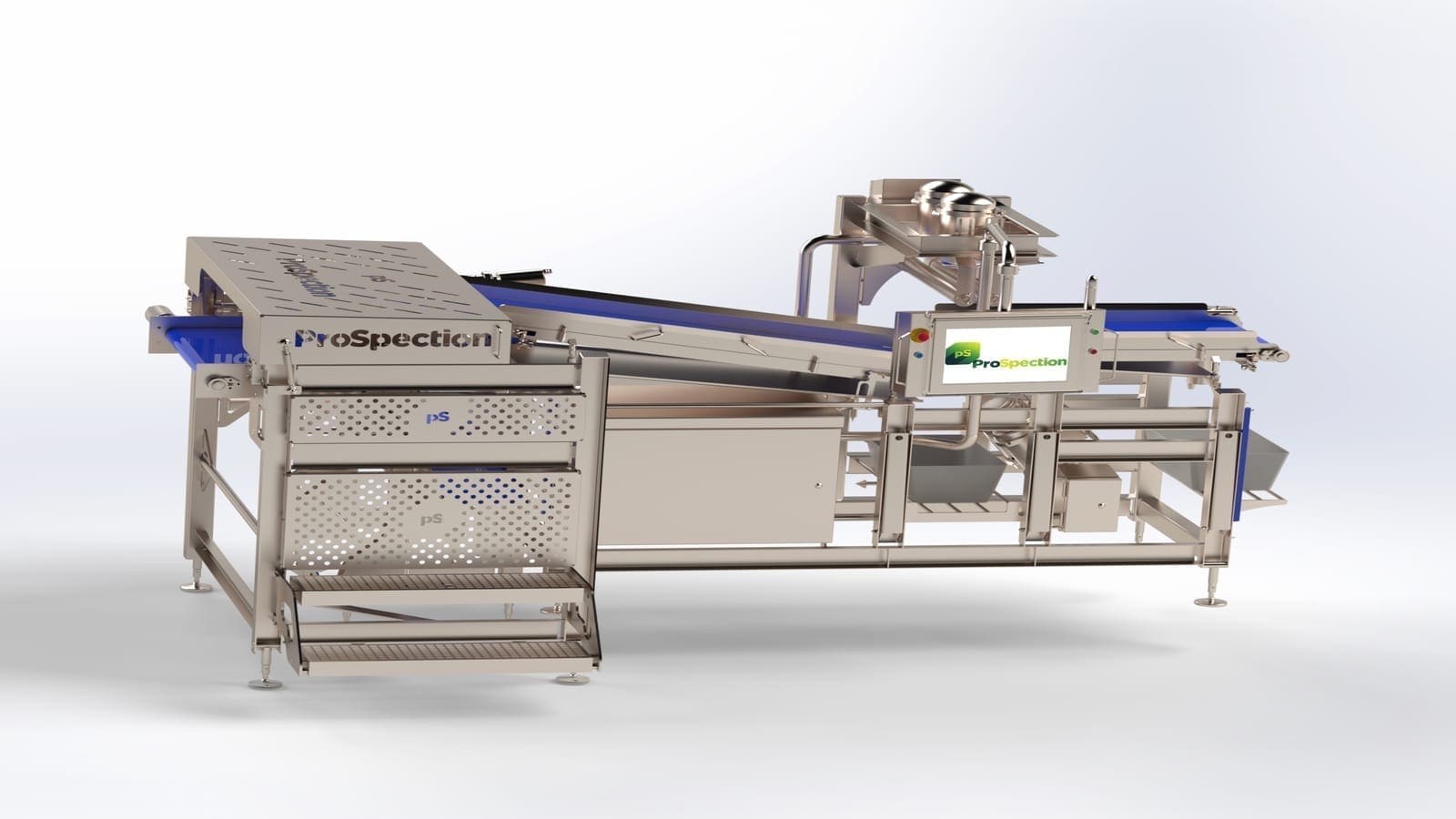

Designing and implementing the system presented several challenges for ProSpection as the system needed to provide a higher throughput, require a smaller footprint and have a higher degree of reliability than competing machines.

The company’s proprietary vision inspection software also needed to communicate in real time with the machine controller to allow for instantaneous removal of contaminants from the production line.

As such, it implemented EtherCAT and PC-based control technologies from Beckhoff.

This offered an intuitive engineering environment in addition to being robust, comprehensive and deterministic.

The foreign material inspection system uses multiple camera angles to scan and inspect the entire surface of beef, pork, poultry, shredded cheese, pasta and other prepared foods.

The machine can detect a wide range of contaminants, including hard and soft plastics, personal protective equipment (PPE) and many items commonly found in production plants which it automatically ejects.

“The foreign material inspection system allows our customers to detect and remove foreign objects from their product stream with a significantly higher degree of consistency, accuracy and at a much higher rate than other inspection methods,

“This system has become Prospection’s flagship product line, drawing attention from the largest CPG manufacturers in the food industry. The attention drawn to the foreign material inspection system has also helped us grow our other product lines. The company also offers inspection systems for roll-stock, block and chub, as well as check-weighing solutions,” says Jeff Youngs, president and CEO of ProSpection.

According to the vice president of technology, Kyle Knudsen, the machine does not have to flip the product to inspect both sides and requires a much smaller footprint than competing systems.

It offers the company’s customers a high-throughput machine with more transparent results.

With fast communication from the inspection software to the motion components over EtherCAT, the system can handle 10,000-25,000 pounds of product per hour with high accuracy. This rate is three to five times higher than typical competitive systems on the market.

The automation system logs inspection results in a SQL database and stores cropped images showing every contaminant with timestamps, allowing the customer to review detected contaminants, eliminate issues in the plant and reduce waste while ensuring high processing speeds and uptime.

In 2017, ProSpection Solutions kicked off its transition from machine distributor to machine builder OEM.

One of the first products its engineering team designed was the IP69K-rated low-density foreign material detection and removal system which won the innovation Showcase Award in the Meat, Poultry and Seafood category in 2019.

This honor reinforced the company’s new direction and its selection of control technologies to automate the machine, including EtherCAT and PC-based control.