U.S – QualiTru Sampling Systems, experts in the field of aseptic and representative sample equipment for the food and dairy sectors, have debuted a new TruStream7 Septum EU created specially to meet the needs of European dairy and liquid food processing enterprises.

The cutting-edge septum, which permits separate samples to be pulled from seven different channels, is EC1935/2004 compliant and rated up to 87°C. It significantly decreases the risk of introducing pollutants during the sampling procedure.

Moreover, it complies with FDA requirements for food contact and is devoid of latex, phthalates, and BPA.

“QualiTru is proud to offer its sampling products with a network of global partners who can provide onsite service and local stock,” says QualiTru.

By performing aseptic inline process monitoring easily and affordably, the TruStream7 Septum EU enables dairy and liquid food processors, as well as dairy farmers, to improve food safety and quality processes.

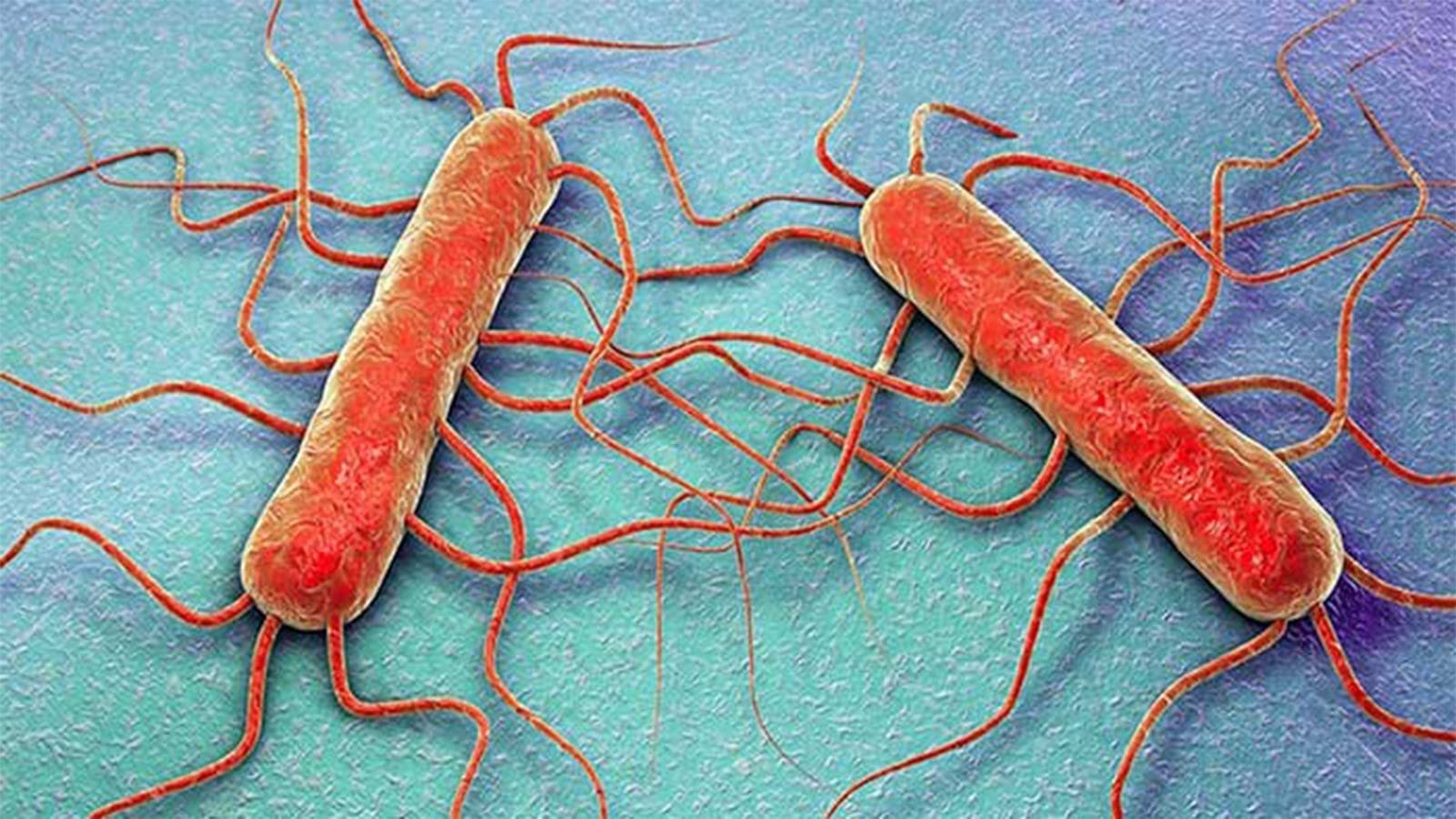

Aseptic inline process monitoring, which is a component of system hygiene monitoring, enables proactive sampling and testing techniques and can improve food quality and safety by identifying and reducing potential microbiological threats early in the production process.

“Finished product sampling provides a global overview of the production but is of very limited interest for root cause analysis in case of deviation. This is where inline sampling is needed, to track the deviation at its source.

“As one needs to be intrusive in an often-closed process, it is paramount to perform aseptic sampling, protecting both the factory sample for further analysis and the production process. Not all available solutions are fit for purpose. Choose wisely how you want to do this,” said François Bourdichon, Ph.D., Food Safety Microbiologist and Chair of the Standing Committee on Microbiological Hygiene, International Dairy Federation.

Formerly known as QMI, QualiTru Sampling Systems received ISO 9001 certification for aseptic sampling for dairy, and liquid food industries last year in May, demonstrating its commitment to world-class quality.

The company also earned 3-A Sanitary Standards certification for its entire line of TruStream Stainless Steel Ports and TruStream Septa for fulfilling Standard 63-04 (Sanitary Fittings).

3-A Sanitary Standards certification is considered the highest industry standard level for integrity and hygiene in processing equipment and systems.

The U.S. Food and Drug Administration (FDA) in Section 6 of Grade “A” Pasteurized Milk Ordinance (PMO), directly cites QualiTru’s technologies as the only inline aseptic sampling system that is approved for the required collection of representative samples directly from farm bulk milk tanks or silos, prior to the milk being transported for processing.

For all the latest food safety news from Africa and the World, subscribe to our NEWSLETTER, follow us on Twitter and LinkedIn, like us on Facebook and subscribe to our YouTube channel.