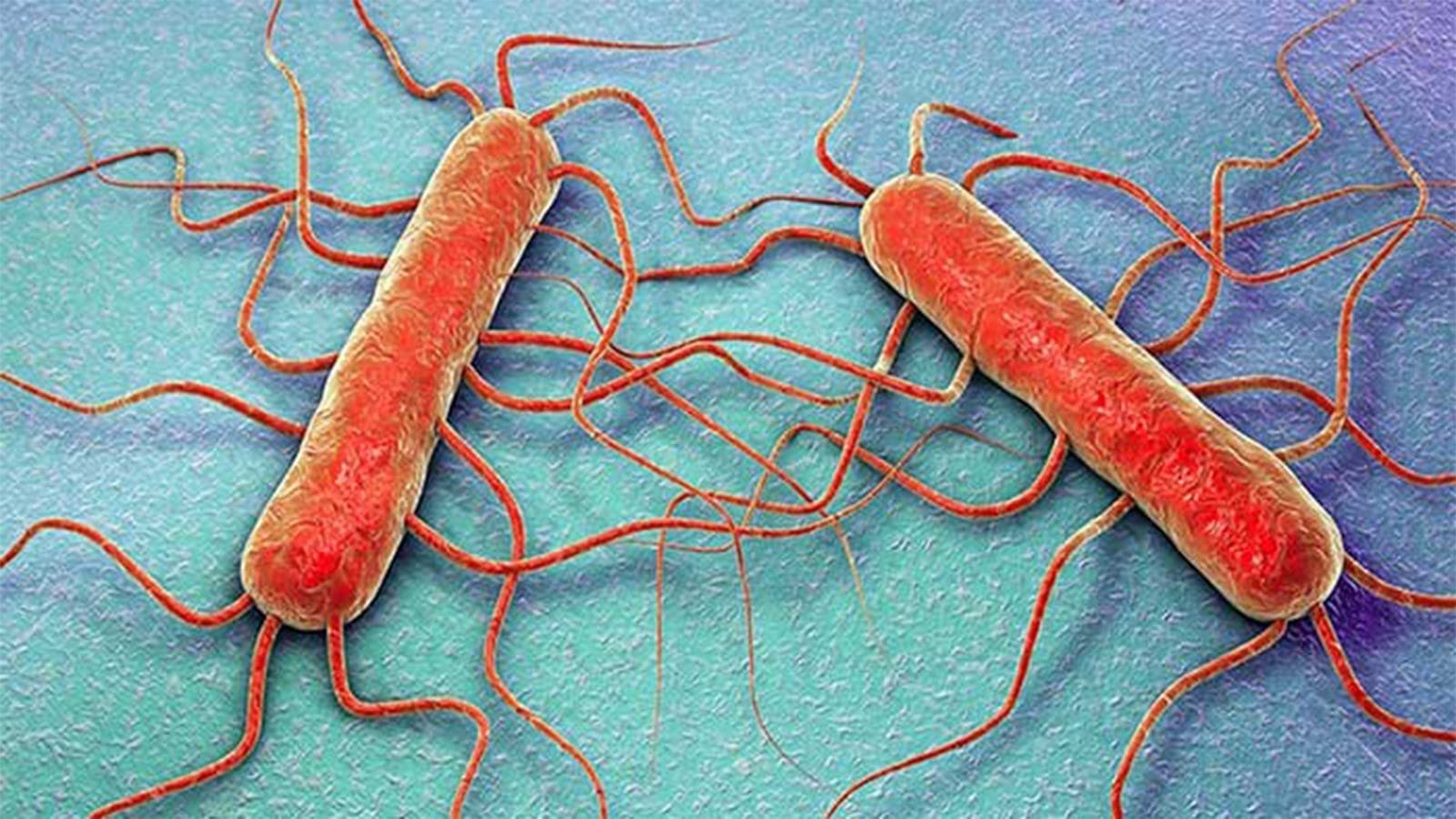

SPAIN- Recent research project funded by the Center for Produce Safety (CPS) has dispelled an earlier hypothesis that thought raw material was the main vehicle for introducing the pathogen Listeria monocytogenes to processing facilities.

This is after the research titled “Identification of Quantitative and Qualitative Patterns of Environmental Contamination by Listeria spp. and L. monocytogenes in Fresh Produce Processing Facilities and Evaluation of Practical Control Measures Able to Eliminate Transient and Persistent Contamination,” found the highest number of positive L. monocytogenes in more remote non-contact surfaces, such as drains, floors, and ceilings across all three facilities that participated in the study.

Ana Allendale, Ph.D., and her group from the Spanish research facility Center for Ecological and Applied Biology of Segura/Superior Council of Scientific Investigations (CEBAS-CSIC) oversaw the two-year study.

The co-principal investigators for Dr. Allendale were Mabel Gil, Ph.D., and Pilar Truchado, Ph.D., both of CEBAS-CSIS.

In order to perform their investigation, the scientists enlisted the aid of three processing facilities with lines for cut iceberg lettuce, cut fruit, and salad bowls.

Although the U.S. Food and Drug Administration (FDA) imposes a zero-tolerance policy for L. monocytogenes in samples of processed produce, the European Commission has set a threshold of 100 colony-forming units (CFU) per gram for the EU where the experiment was done.

Dr. Allendale’s team started by segmenting processing sections into three zones depending on their proximity of contact with the product in order to better study how zoning, sanitary design, and connectivity affected the contamination of produce.

At the conclusion of each day, the facilities were routinely sampled by the researchers before being cleaned and sanitized. Following cleaning and disinfection, samples from the three processing lines were again taken.

The scientists also gathered 45 samples of raw materials and finished products in addition to the more than 600 total samples they obtained from the three zones. The researchers identified the points of contamination ingress by sampling the processing plants before and after cleaning and disinfection.

In all three participating sites, Zone 3 had the highest percentage of positive L. monocytogenes, according to the sampling performed by the researchers.

To determine whether the L. monocytogenes strains detected in the facilities were transient or persistent, the CEBAS-CSIS team then performed WGS on 100 samples. Unexpectedly, samples taken both before and after cleaning revealed the same two serotypes of the pathogen on all three production lines.

The discovery made by WGS implies that the L. monocytogenes serotypes identified from the facilities are inherent and are shifting from Zone 3 to Zone 1. This finding contradicts the researchers’ initial theory that raw materials were the primary means of transferring the pathogen to facilities.

Biocide effectiveness

The researchers then tested the effectiveness of the biocides against local L. monocytogenes isolates and showed that all of the isolates they had collected from the environment after cleaning were vulnerable to the biocides employed.

Despite the sanitizers’ effectiveness, the researchers noted that cleaning tasks are frequently not carried out properly, which permits germs to survive in the environment.

The three participating processing plants and the industry at large can put the study’s conclusions to use, reports Food Safety Magazine.

According to Dr. Allendale, the study should aid processors in comprehending the primary contamination spots in Zone 1 and how they relate to the same or comparable L. monocytogenes sequencing types in Zones 2 and 3.

She will deliver the project’s final report at the 2023 CPS Research Symposium, which will be held in Atlanta, Georgia, June 20–21.

For all the latest food safety news from Africa and the World, subscribe to our NEWSLETTER, follow us on Twitter and LinkedIn, like us on Facebook and subscribe to our YouTube channel.