U.S. – Award-winning food robotics company Soft Robotics Inc. has announced that it has raised a USD $10M Series B extension, to expand commercial operations to meet COVID-19 pandemic-fueled demand and launch its SoftAI powered robotic solutions.

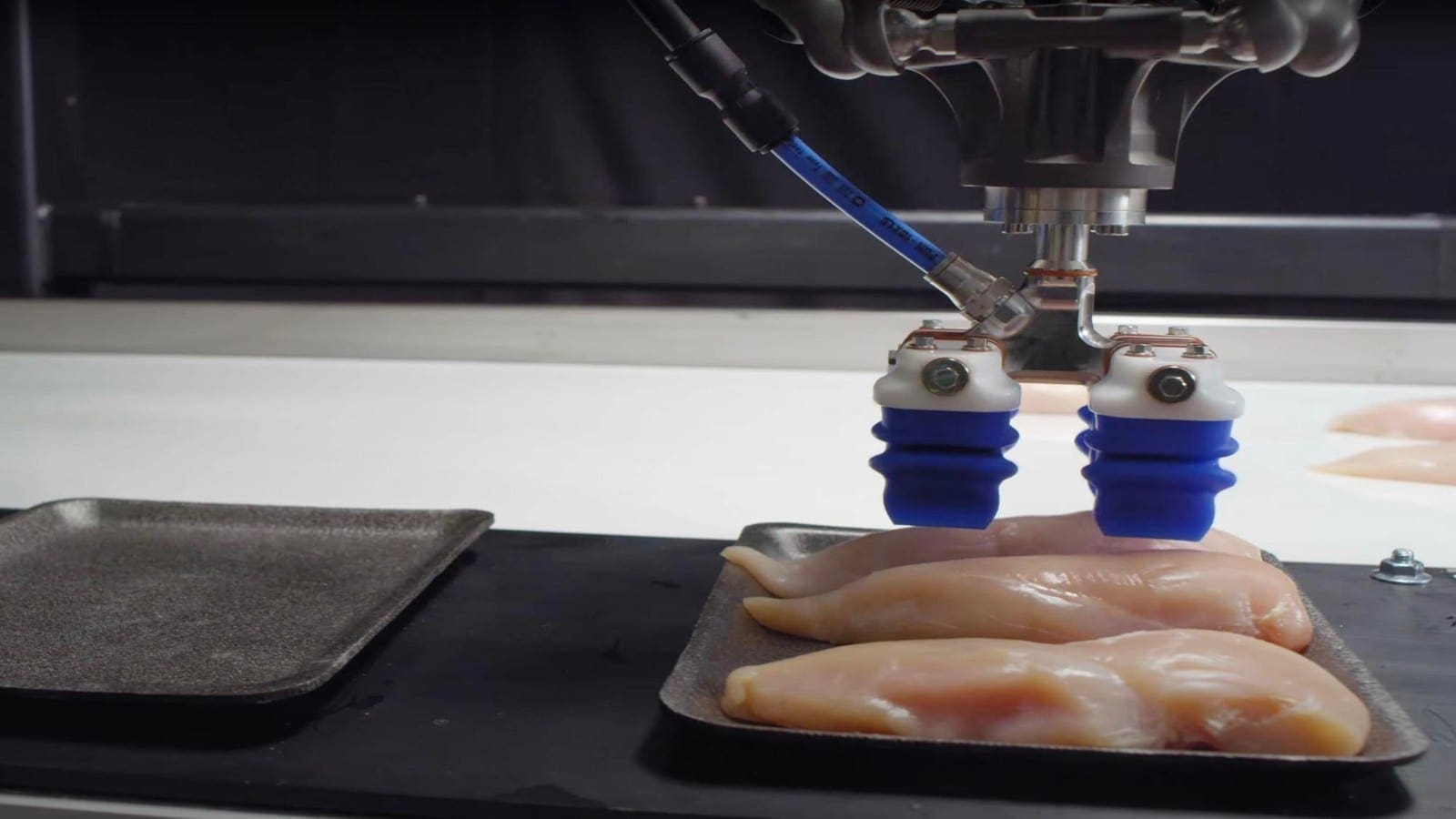

SoftAI layers 3D vision and artificial intelligence technologies, on top of Soft Robotics’ patented and proven, IP69K-rated, soft grasping to give industrial robots the hand-eye coordination of human beings.

The IP69K rating provides protection against entrance of dust and high temperature, high pressure water, making products with this certification ideal for use in conditions where equipment must be carefully sanitized.

This extraordinary combination of robotic “hands,” “eyes” and “brains” enables, for the first time ever, the automation of bulk picking processes e.g. bin picking, in the food supply chain.

The round was co-led by Material Impact, Scale Venture Partners, and Calibrate Ventures and brings Tyson Ventures, the venture capital arm of Tyson Foods into the syndicate.

ABB Technology Ventures and Tekfen Ventures also participated to complete the round.

Soft Robotics’ robotic technology, computer vision and AI platform have the potential to transform the food industry.

“Today’s industrial robots are unable to deal with product variability or unstructured environments, typically found across the labor challenged food supply chain, in areas such as agriculture, food processing, and logistics,”

“With our revolutionary soft grasping, 3D perception, and AI technologies, Soft Robotics unlocks robotic automation by augmenting widely available industrial robots with true hand-eye coordination, allowing them to perform tasks that traditionally could only be performed by human workers,” said Mark Chiappetta, COO at Soft Robotics.

Tyson foods

Companies such as Tyson Foods, are betting on adoption of robotic automation to help improve safety and increase production in their facilities to meet the demand for high quality, safe and nutritious protein products.

Tyson Foods, an existing user of soft robotics, is a leading producer of chicken, beef, and pork, and has invested about USD $500 million in new technology and automation in the last three years.

“At Tyson Ventures, we are continually exploring new areas in automation that can enhance safety and increase the productivity of our team members,”

“Soft Robotics’ best-in-class robotic technology, computer vision and AI platform have the potential to transform the food industry and will play a key role in any company’s automation journey,” said Rahul Ray, Senior Director of Tyson Ventures.

The global COVID-19 pandemic has heightened the pressure to automate, so as to mitigate workforce challenges and increase operational and food safety in factory environments.

Soft Robotics has experienced a rapid increase in demand for its products and has delivered the two largest sales quarters in the company’s seven-year history.

Jeff Beck, CEO at Soft Robotics alluded that vulnerabilities of the food supply chain were illuminated by the pandemic, making it clear that automation has graduated from a nice-to-have to a must-have, across all large-scale food production operations.

Soft Robotics patented technologies are ready and being used to enable automation in the processing and packaging of proteins, produce and bakery products.

Demand for both hardware and SoftAI software solutions are increasing at a remarkable pace.

This new capital will support Soft Robotics’ exponential growth thereby ensuring automation plays a major role in safeguarding the food supply against future disruptions.

Companies in these sectors are briskly adopting SoftAI in their factories to automate picking and sorting of fragile or irregularly-shaped products such as meats, produce, and seasonal items that previously had to be hand-sorted.